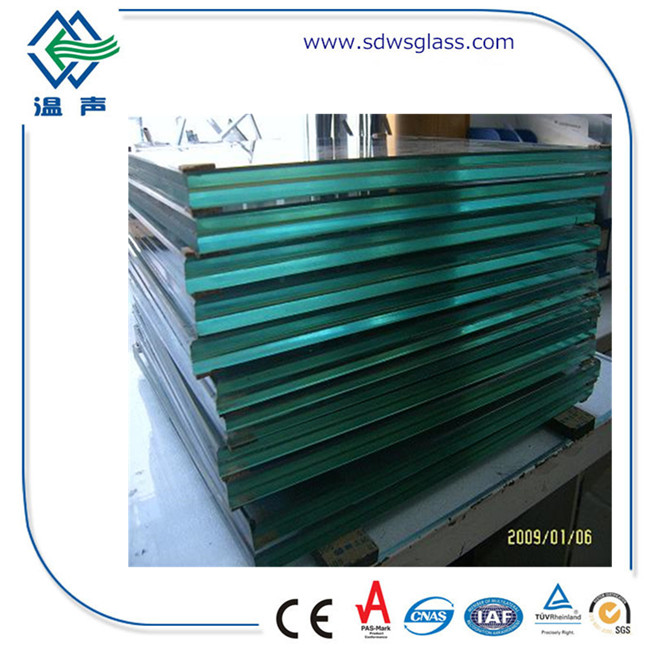

Clear Tempered Laminated Building Glass

Laurel laminated glass is produced with two or more thoroughly cleaned panels with one or more polyvinyl-butyralfoils(PVB) are mounted on each other in a clean room. Then the sandwich is pre-strengthened in a rolling process at approx. 200℃ heat and then put these glasses on a shelf into the autoclave with about 130℃ heat and 10 bar pressure. With the sharp increasing of safety glass in all aspects of life, laminated glass has become a key component in the realization of modern interior decoration and exterior architecture due to its strength and safety features such as hurricane and impact resistance, protection against bombs or other explosions, sound reduction, glass floors and stairs, earthquake resistance, doors and windows.

Product name | Laminated glass/Sandwich glass |

Features | 1.Holds together when shattered. The PVB interlayer keeps the glass bonded, even when broken, resulting in a characteristic spider web cracking pattern across the glass 2.Cyclone resistant 3.Superior UV blockage 4.Excellent sound damping properties 5.Low visible distortion |

Application | 1.skylight 2.office partition 3.shower door 4.sliding door 5.balustrade 6.balcony 7.window 8.curtain wall 9.glass stairs 10.glass railing |

Thickness | 3+3 4+4 5+5 6+6 8+8 10+10 12+12 The thickness and size can be designed for customer |

Size | Min size:300*300mm |

Max size:2800*4200mm | |

Color | clear, ultra clear, blue, green, red, rey, bronze, black, yellow |

Moq | 100sqm |

certificate | CE CCC CSI ISO |

Package | Fumigation-free plywood crates with paper or cork pad between each sheet glass, sutiable for long distance ocean transportation |

Related News

Submitted successfully

We will contact you as soon as possible