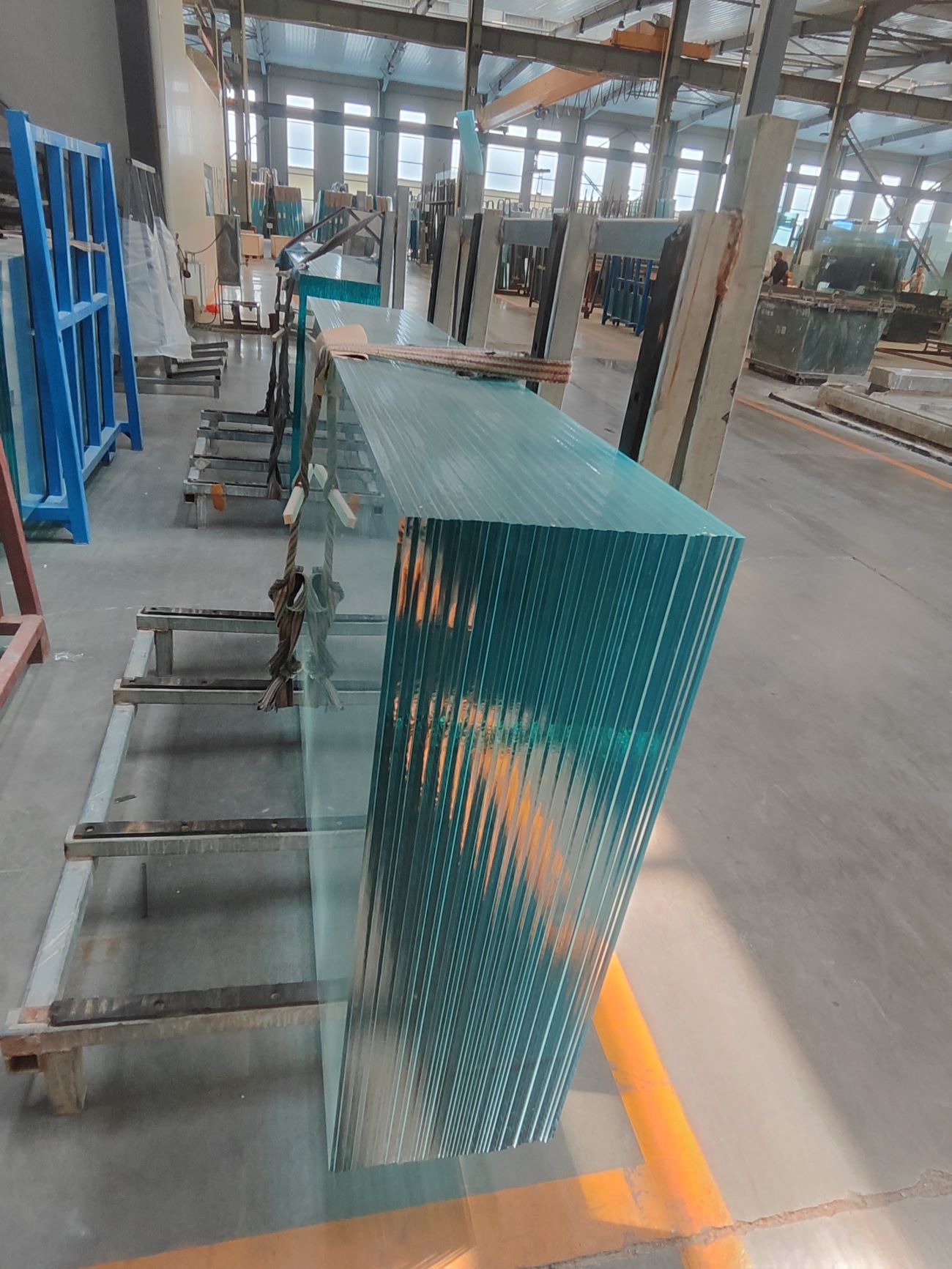

6mm Tempered Super White Anti-reflective Film Glass

● The highest peak value of visible light transmission rate is 99%, and the average visible light transmission rate is over 95%, which significantly improves the original brightness of LCD and PDP and reduces energy consumption.

●The average reflection rate is less than 4%, and the lowest value is less than 0.5%.

●Effectively weakening the defect of white screen caused by the strong light behind, enjoying clearer image quality.

UV resistance, effective eye protection The transmission rate of UV spectrum area is greatly reduced, which can effectively block the UV damage to the eyes.

High temperature resistance: AR glass can withstand temperatures of >500 degrees (compared to 80 degrees for general acrylic).

●More colorful and stronger contrast, making the image color contrast more intense and the scene more clear.

The hardness of AR glass film layer is comparable to that of glass, greater than 7H (the hardness of general PC board is about 2H to 3H).

The film layer is resistant to various cleaning agents and acid and alkali cleaning agents, and the film layer is not damaged.

The impact resistance of 3mm thickness glass is equivalent to 6mm acrylic.

The surface flatness of AR glass is much better than coated acrylic, and the larger the size, the more obvious the difference.

●Keeping the view angle, generally the view angle of acrylic will become smaller after installation; while the view angle will not become smaller after AR glass is installed.

●The cold and heat deformation of AR glass can be almost omitted, which is suitable for all kinds of environments; meanwhile, AR glass has a glazed feeling and more beautiful appearance.

It is a kind of glass with special treatment on the surface of the glass. The principle is to process the high quality glass on one or both sides. Compared with ordinary glass, it has a lower reflection ratio, so that the reflectivity of light is reduced to less than 1%, the ordinary glass in the visible range, its one-sided reflectivity is about 4%. The total spectral reflectance is about 8%. Glass surface in the visible range of reflectance reduction effect can be achieved by two methods; one for the use of different optical materials film layer to produce interference effects to eliminate incident light and reflected light, thereby improving the transmission method, such use of light phase extinction interference production of glass called AR glass; another method is to use the scattering effect of the rough surface to convert a large amount of incident light into diffuse light reflection, it does not give This kind of glass produced by fine roughing is called AG glass.

● The highest peak value of visible light transmission rate is 99%, and the average visible light transmission rate is over 95%, which significantly improves the original brightness of LCD and PDP and reduces energy consumption.

●The average reflection rate is less than 4%, and the lowest value is less than 0.5%.

●Effectively weakening the defect of white screen caused by the strong light behind, enjoying clearer image quality.

UV resistance, effective eye protection The transmission rate of UV spectrum area is greatly reduced, which can effectively block the UV damage to the eyes.

High temperature resistance: AR glass can withstand temperatures of >500 degrees (compared to 80 degrees for general acrylic).

●More colorful and stronger contrast, making the image color contrast more intense and the scene more clear.

The hardness of AR glass film layer is comparable to that of glass, greater than 7H (the hardness of general PC board is about 2H to 3H).

The film layer is resistant to various cleaning agents and acid and alkali cleaning agents, and the film layer is not damaged.

The impact resistance of 3mm thickness glass is equivalent to 6mm acrylic.

The surface flatness of AR glass is much better than coated acrylic, and the larger the size, the more obvious the difference.

●Keeping the view angle, generally the view angle of acrylic will become smaller after installation; while the view angle will not become smaller after AR glass is installed.

●The cold and heat deformation of AR glass can be almost omitted, which is suitable for all kinds of environments; meanwhile, AR glass has a glazed feeling and more beautiful appearance.

By coating the surface of ordinary tempered glass, it improves the light transmission of the tempered glass surface and achieves easy cleaning function. AR coated glass can be mainly used in solar cell modules, solar thermal, architectural, automotive glass, etc.

Related News

Submitted successfully

We will contact you as soon as possible